- About us

-

Products

CLASIFICATION

SECTOR

APPLICATION

CROPS

PRODUCTS

- SUSTAINABILITY

- Downloads

- Corporate Governance

- Contact

Products

Double screen

Double screen

Film to improve crop thermal protection

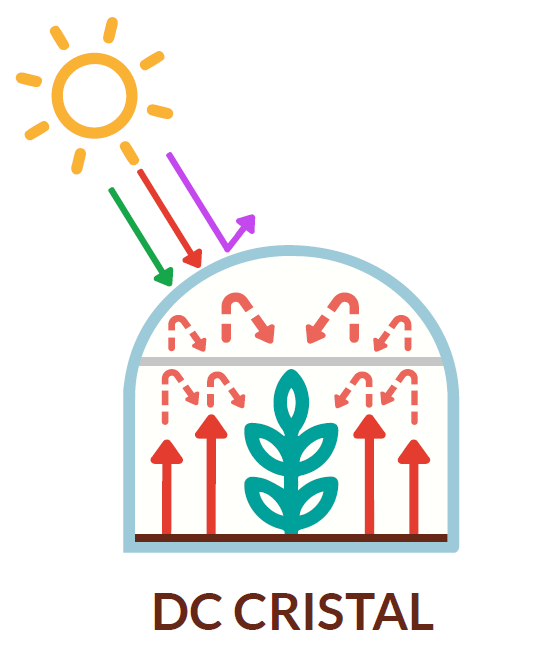

Plastics for double screen greenhouses amplify the thermal effect of the cover and in turn allow for maximum light transmission towards the greenhouse interior.

Their purpose is to create an air chamber, or insulation, between the cover plastic and the double chamber that regulates the temperature, reducing temperature variations and mitigating plant stress.

Another advantage is that the double screen protects the crop from potential dripping from the greenhouse cover, especially in “ridge and furrow” structures.

They can be manufactured with 10 or 15 mm-diameter perforations, to improve ventilation inside the greenhouse and in turn, avoid water from pooling on top of the double chamber.

They have a thermal effect that magnifies the greenhouse cover’s effect.

SOLPLAST’s double screen plastic is made with resins that notably improve visible light transmission inside the greenhouse, minimising light loss in the crop area.

Prevents drops from forming inside the sheet due to condensation inside the greenhouse. Instead of drops, it forms a continuous sheet of water, which at the proper slant of the double layer film, slides towards the greenhouse strips, avoiding drips onto the plants and reducing the risk of diseases.

They can be produced with 10 or 15 mm-diameter perforations to improve ventilation inside the greenhouse.

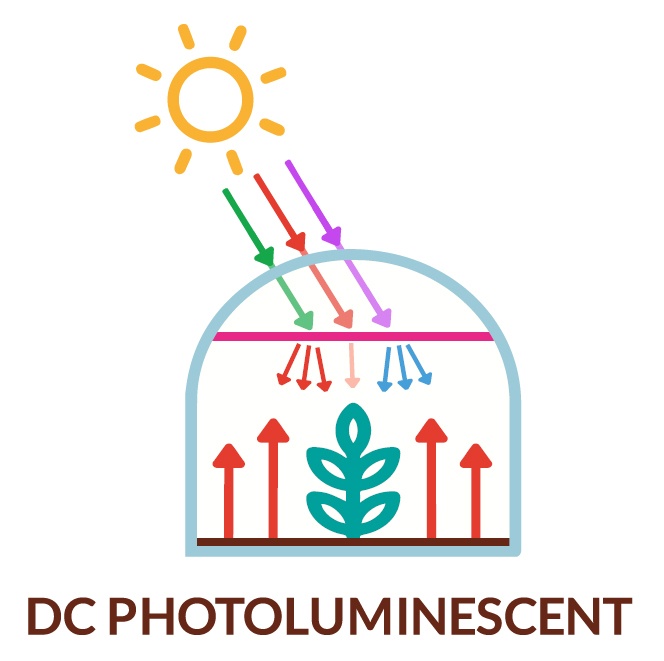

The double layer Photoluminescent option is designed with additives that modify the PAR spectrum, transforming the green light that cannot be used by the plants into yellow/red light.

100% recyclable materials.

-

They have a thermal effect that magnifies the greenhouse cover’s effect.

-

SOLPLAST’s double screen plastic is made with resins that notably improve visible light transmission inside the greenhouse, minimising light loss in the crop area.

-

Prevents drops from forming inside the sheet due to condensation inside the greenhouse. Instead of drops, it forms a continuous sheet of water, which at the proper slant of the double layer film, slides towards the greenhouse strips, avoiding drips onto the plants and reducing the risk of diseases. .

-

They can be produced with 10 or 15 mm-diameter perforations to improve ventilation inside the greenhouse.

-

The double layer Photoluminescent option is designed with additives that modify the PAR spectrum, transforming the green light that cannot be used by the plants into yellow/red light.

-

100% recyclable materials.

RANGE OF AVAILABLE PRODUCTS

DC SOLTERMThe highest heat conductivity in your greenhouse. |

|

DC CRYSTALThe highest transparency and visible light penetration for your crop. DC CRYSTAL PLUSIt achieves almost 100% clarity in your greenhouse with the most transparent film on the market. |

|

DC PHOTOLUMINESCENTIncreases the available PAR for plants. |

|

A universe of solutions

-

Documents

Download documents, catalogues and all kinds of information of interest -

Distributors

Locate your closest distributor, or call us at (+34) 968 461 311. -

TECHNICAL ASSISTANCE

Do you need help? Contact us and one of our consultants will answer your questions

Solplast is the agricultural plastics division of the Armando Alvarez Group. We have been transforming farming since 1986 through research, technology and creativity in specialised plastics. We cover all market needs, from start to finish, with the widest and most specialised range of agricultural plastics.

FOLLOW US Linkedin Facebook Youtube Instagram